The Roast Process

Roasting is the alchemical process that turns green coffee beans into the aromatic brown beans we know and love. This transformation is an intricate dance of time, temperature, and the keen senses of the roaster.

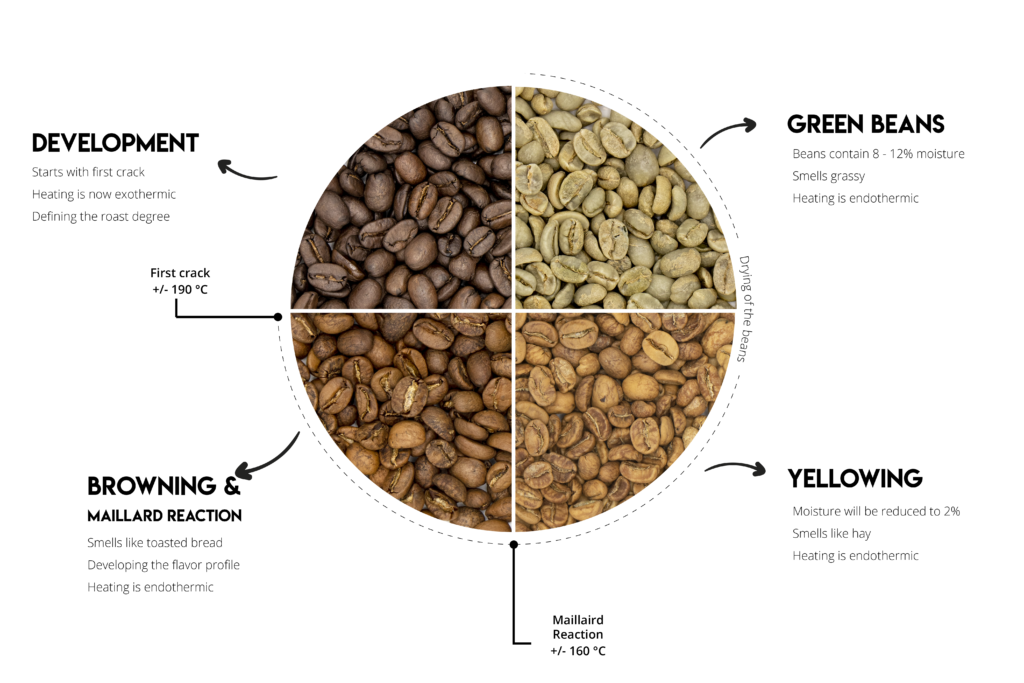

The Drying Phase (Initial Stage)

- Temperature Range: Starts around room temperature and goes up to approximately 160°C (320°F).

- Duration: 4-8 minutes, depending on the bean and desired roast profile.

- Purpose: Green coffee beans contain about 10-12% moisture. The drying phase is essential for removing this moisture and preparing the beans for the reactions that follow. During this stage, you’ll hear a soft, papery rustling as water evaporates.

The Maillard Reaction

- Temperature Range: 160-180°C (320-356°F).

- Duration: This stage can last anywhere from 3-6 minutes.

- The Science: Named after French chemist Louis Camille Maillard, this reaction is where sugars and amino acids interact to create complex flavours and brown the beans. Here, the aromas of toasting bread and light caramel emerge as the beans start to transition from grassy to nutty, setting the stage for more developed flavours.

- Visual Changes: The beans turn from pale green to light brown.

First Crack (Turning Point)

- Temperature Range: Approximately 196-205°C (385-401°F).

- Duration: A brief but significant phase.

- What Happens: As internal pressures build from the heat, the beans release pent-up steam with an audible “crack,” similar to popcorn popping. This is a critical marker indicating that the beans have shifted from endothermic (absorbing heat) to exothermic (releasing heat) reactions.

- Flavour Development: Reaching the first crack means the beans are now at a light roast. They feature bright acidity and maintain more of their origin characteristics.

Development Phase

- Temperature Range: 205-220°C (401-428°F), depending on desired roast.

- Duration: Varies from 1-4 minutes, shaping the final flavour.

- Flavour Transformation: The development phase is when caramelization deepens, and complex flavours such as chocolate, spice, and darker fruits start to come through. A longer development phase can mellow acidity and introduce bittersweet notes.

- Key Decision Point: Roasters must carefully monitor this phase to avoid over-roasting, which can lead to burnt or flat flavours.

Second Crack (Dark Roasts)

- Temperature Range: Around 224-230°C (435-446°F).

- What Happens: A second, quieter “crack” occurs as the cellulose structure of the beans starts to break down further. This is where dark roast profiles, such as French or Italian roasts, are achieved.

- Flavour Profile: Second crack marks the transition into oils migrating to the surface, producing roasts that are richer and more bittersweet, often with smoky or charred notes. However, prolonged roasting beyond this point risks losing the unique flavours of the bean and can introduce an ashy taste.

Post-Roasting: Resting and Degassing

Freshly roasted coffee needs time to “degas,” as it releases CO2 built up during the roasting process. For optimal flavour, most coffees should rest 24-72 hours post-roast, but some delicate profiles may benefit from even longer resting periods.

Variables that Influence the Roast

- Bean Density: Denser beans, often from higher altitudes, require more heat input.

- Moisture Content: Higher moisture can extend the drying phase.

- Origin Characteristics: Some beans excel as light roasts to highlight floral and citrus notes, while others benefit from deeper roasting to emphasize chocolate and nutty tones.

- Heat Application: Whether you choose to ramp up the heat quickly or let it gradually build will impact the final cup profile.

- Airflow and Agitation: Proper airflow helps control temperature and remove chaff, while agitation ensures even roasting.

iv